Golf 1.8T 20V Tuning Project

Big 1.8T tuning project: Our test golf achieves 700 hp!

In 2005 the BAR-TEK fleet was increased by a Golf IV GTI 1.8T. It should be a 1999 AGU with 150 hp. This 1.8T engine was one of the first 20V (valves) built by VW on the market to replace the successful G60 G-Lader series. The AGU engine belongs to the still quite "simple" and "stupid" engines, because it has no correct boost pressure control. This means that the engine control has no boost pressure sensor to control the actual boost pressure. Instead, the entire control system is controlled by the susceptible air mass sensor. The 1.8T AGU engine has the better connecting rods and large intake ducts in the cylinder head without variable valve timing adjustment (VVT).

Profile Golf

(nach fünfter Stufe)

| Brand | Volkswagen |

|---|---|

| Model | Golf |

| Performance | 700 PS |

| Torque | fehlt |

| Maximum speed | fehlt |

| From 0 to 100 | fehlt |

| Engine | fehlt |

| Gearbox | fehlt |

| Weight | fehlt |

Before we went to the tuning of the 150 hp engine, first the usual sources of errors were excluded:

- Read fault memory with VAG-COM

- New intake air temperature sensor

- Upgrade ignition coils with matching adapter plates

- New air mass meter (LMM)

- New hose for crankcase ventilation

- Cleaning the throttle valve with readjustment via VAG-COM

- New water temperature sensor

- New fuel filter

- New RS water thermostat with faster opening time

1) The first 1.8T tuning project:

- Large front intercooler from a German manufacturer from Lübeck (This intercooler kit proved to be a big challenge concerning the installation). The first test run showed that the intake air temperature was too high.)

- Lightweight aluminium belt pulleys

- Upgrade pressure pipe between turbocharger and intercooler

- K&N plate filter

- Pop-off valve splitter BAR-TEK®

- Chip tuning (Eprom)

You can also buy the built-in parts in our 1.8T tuning kit stage 1. So you have everything matching each other in one set.

2) Tuning project number two: Some upgrades it should be!

- K04-001 RS Upgrade turbocharger and new turbo oil piping

- Upgrade slotted turbo manifold

- Upgrade bolts for manifold

- 3" Downpipe

- 200 cell metal cat

- 3" exhaust system with low backpressure due to absorption silencer

- 380 ccm Bosch injectors

- Eprom adjusted

- Adjustable fuel pressure regulator BAR-TEK®

- Forge intake hose

- VR6 LMM housing (Only the housing of the VR6 because of the larger cross-section of 70mm; part number: 021 906 462A)

- VR6 K&N "Mushroom" Air filter (Not recommended due to LMM malfunction)

- Sachs sports clutch with single mass flywheel (SMF) and ARP bolts

- NGK Race spark plugs

- 6-speed Golf 5 gearbox with Peloquin differential lock

- Innovative Lambda Tool

- Brembo GT front brake

- Forge Carbon Strut

- H&R chassis

- H&R Stabi Kit complete

- Powerflex chassis sockets

- INDIGO boost pressure gauge from NewSouthPerformance

- INDIGO oil temperature display from NewSouthPerformance

- AEM X-Series Exhaust Temperature Gauge-Kit

- NewSouthPerformance steering wheel instrument holder

- 3-fold instrument holder from NewSouthPerformance

- Vibra-Tech engine mount

KKK04-001 RS turbocharger ready for installation.

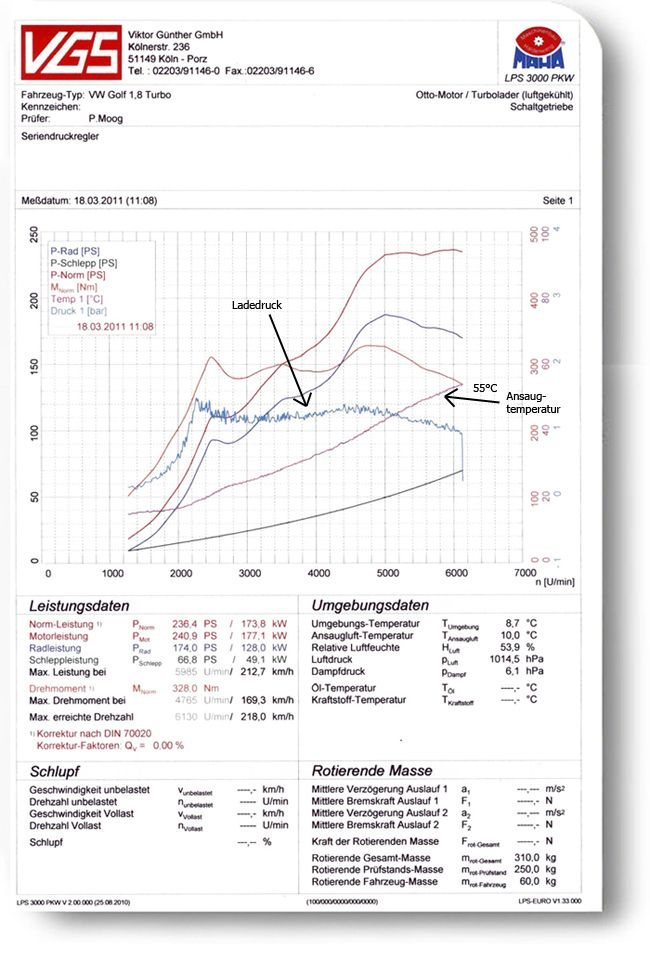

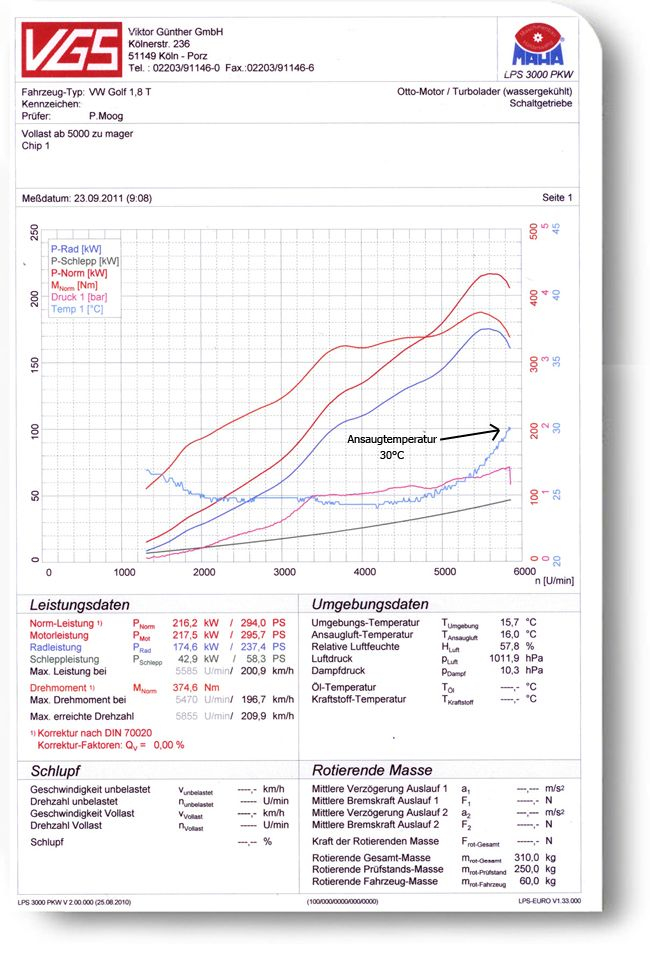

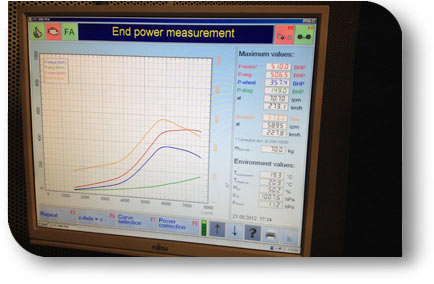

After each tuning stage we have a performance measurement on the dynamometer to see the end result for ourselves:

Conversion to R32 bumper was not only a visual eye-catcher, but also necessary to accommodate the large EVO intercooler.

Comparison between K04-001 and Garrett GT28RS turbocharger.

3) Third 1.8T Tuning Project:

We continued with the conversion to the first Garrett GT28RS turbocharger. This upgrade showed why a conversion to a Garrett turbocharger makes sense but is also expensive. Because the Garrett Turbo is in a different position than a KKK turbocharger, all connections are also different. The upgrade kit contains the appropriate oil and water lines, and the downpipe is also exactly right for any 1.8T with a transverse engine. Also, the intake kit fits relatively well, only the new 90° hose which is attached to the turbocharger had to be shortened a bit. No problem yet, but the exit from the turbo to the intercooler had to be completely re-welded and adjusted by the new position of the turbo. Also, the hoses of the N75 as well as of the SUV (blow-off valve) had to be newly manufactured. At the end of the day, a lot of adjustment work was necessary, but the work should also be rewarded. We measured almost 300 hp with the GT28RS, whereby we had to state on the dynamometer that the original fuel pump did not bring sufficient output volume. With a new pump, there would have been more for sure. We installed the following components with the kit:

Stage 4 Turbokit consists of:

- Complete Garrett GT28RS turbocharger with flange on 3 inches

- Suitable oil and water pipes plus oil restrictor

- 470ccm Bosch injectors

- 3" inch downpipe for Garrett turbocharger

- slotted turbo exhaust manifold, T25 flange

- Intake kit 3 inch with K&N air filter

In addition, these components were used:

- EVO intercooler (very good intercooler, intake temperature never rose above 40°C)

- SEM intake manifold with heat seal from New South Performance

- Software adapted for GT28RS Turbokit

- Oil cooler kit with short oil filter

In addition to the SEM intake manifold, we also installed a 70mm throttle valve from the VR6. Unfortunately, we had constant problems with the basic adjustment of the throttle valve. Also, the exchange of the complete throttle valve did not bring any success. Constantly the error occurred that the lower stop of the throttle valve cannot be calibrated and at idle the engine ran unclean. We would recommend conversion to a larger throttle only from a power of 400 hp upwards, preferably together with the electronic accelerator pedal without throttle cable as on the Golf 4 R32. However, the complete bracket for the throttle, clutch, and brake pedal must also be replaced during this conversion.

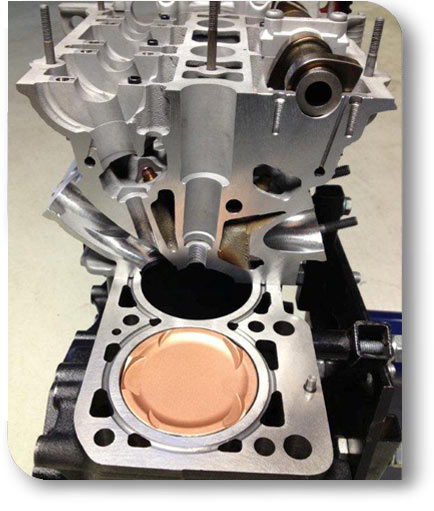

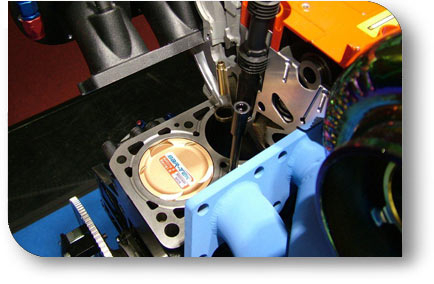

4) The fourth upgrade was serious: the Golf gets a racing engine

We then used the 2011 winter break to completely remove the engine. We would have had to replace the connecting rods from a power output of 300 hp upwards, so we modified the whole engine immediately. Our goal was to build the engine as stable as possible, because we didn't want to take any risk of getting an engine breakdown. In addition, the fuel supply was directly large enough to drive with E85. E85 has many advantages with turbo engines: better knocking characteristics due to higher octane number, more pre-ignition possible and therefore more engine power, better cooling effect and less deposits in the combustion chamber.

Our racing engine was used with the following components:

- Integrated i-beam connecting rods VW Tuscan

- JE Forged pistons with coating

- Race main bearing shells

- ACL Connecting rod bearing shells

- Billet crankshaft

- Main bearing girdle

- High torque timing belt gear kit

- ARP bolts for crankshaft and camshaft wheel

- Integrated camshaft sprocket

- Integrated mechanical timing belt tensioner

- Gates timing belt Race blue

- Schrick camshafts

- Supertech valve spring kit titanium (Not recommended for power over 400 hp. In this case Schrick would be better)

- Inconel exhaust valves (Not recommended for power above 400 hp. In this case Schrick would be better.)

- Inlet valves Schrick

- CNC ported cylinder head by BAR-TEK

- Hydraulic lifters

- ARP cylinder head spacer bolts

- Sachs RCS 184 sports clutch with Friction Disc and BAR-TEK® Flywheel Bolts

- 02M 6-speed gearbox like R32 with reinforced drive shafts and Peloquin differential

- Top Mount turbo exhaust manifold T25 with ceramic coating

- Garrett GTX28/67 Turbocharger

- Dual surge tank with 2 Bosch 044 fuel pumps in engine compartment for E85 operation

- BAR-TEK® fuel pump

- Aeromotive Fuel Filter

- Aeromotive fuel pressure regulator Dash 10, with manometer

- Dash 10 BAR-TEK® fuel bar

- Teflon Dash hoses

- Siemens DEKA injection valves

- Freely programmable motor management from KMS

- Racing alternator BAR-TEK®

- BAR-TEK air filter system suitable up to 1000 hp

- BAR-TEK pop-off valve splitter

- Forge water hoses

- RS water thermostat and temperature switch

5) After the fifth tuning project up to 700 hp!

Now it went again a stage further with a Garrett GTX30 turbocharger.

The only change in the interior of the engine were the pistons, because we had to reduce the compression to 8.5:1. Since we "cheer" the engine with E85 (bio ethanol), we did not have to go further down to 8.0:1.

Further parts, which were assembled:

- upgrade top mount Turbo exhaust manifold with T3 flange

- Tial blow off valve

- Gearbox maximum reinforced

- Injector Bosch injectors

As a final result after the fifth tuning project we could measure a full 700 hp in our 1.8T test golf!

We continue with the next level 6 on Garrett GTX35 Turbo!

Our test Golf in the "VW Scene" in May 2013.

More pictures and current news are on our FACEBOOK page.